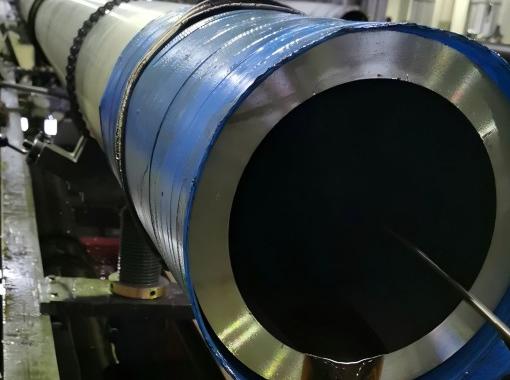

ST52 Chrome Plated Tube

ST52 Chrome Plated Tube

ST52 chrome plated tubes are precision-engineered tubes made from high-strength ST52 steel with a hard chrome-plated surface. These tubes are widely used in hydraulic and pneumatic systems where durability, corrosion resistance, and smooth operation are critical.

Advantages

1. Exceptional Wear Resistance:The hard chrome plating (20-50μm thick) provides a surface hardness of 800-1000 HV (Rockwell C 65-70), significantly reducing wear from friction and abrasive particles.Extends the service life of hydraulic cylinders, minimizing frequent replacements.

2. Superior Corrosion Protection: The chrome layer acts as a barrier against moisture, chemicals, and oxidation, making these tubes ideal for harsh environments (marine, industrial, and agricultural applications).More cost-effective than stainless steel while offering comparable corrosion resistance.

3. Low Friction & Smooth Surface Finish: The polished chrome surface (Ra 0.1-0.4μm) ensures smooth piston movement, reducing energy loss and improving efficiency.Enhances seal performance, preventing leaks and reducing maintenance needs.

4. High Strength & Load-Bearing Capacity: ST52 chrome plated tube is made from ST52 steel, which has a high yield strength and tensile strength.Suitable for heavy-duty applications in construction, mining, and industrial machinery.

5. Cost-Effective & Low Maintenance: Longer lifespan than unplated or painted tubes, reducing downtime and replacement costs.

6. Versatility: Suitable for a wide range of applications, including hydraulic cylinders, pneumatic cylinders, and precision engineering components.

Material Composition

| Element | Composition |

|---|---|

| Carbon (C) | ≤ 0.22% |

| Silicon (Si) | ≤ 0.55% |

| Manganese (Mn) | 1.00 – 1.60% |

| Phosphorus (P) | ≤ 0.025% |

| Sulfur (S) | ≤ 0.025% |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength | ≥ 355 MPa |

| Tensile Strength | 490-630 MPa |

| Elongation | ≥ 22% |

Delivery Conditions

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation.Appropriate further processing allows a certain degree of cold forming(e.g.bending,expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process.Subject to appropriate processing conditionsthe increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Delivery Condition: SR,BK, BK+S, GBK, NBK

ID Size : 20mm – 1500mm

Length: max 16m

Chrome Thickness: 20-100Micron

Type: Seamless, Hot Rolled, Cold Rolled, Cold Drawn

Straightness: ≤ 0.5/1000

Roughness: 0.2-0.4 u

Tolerance EXT: DIN2391, EN10305, GB/T 1619,GOST 8731,GOST 1050,GOST4543

Tolerance INT: H7,H8,H9

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or Plywood case