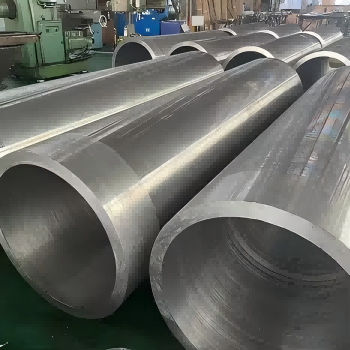

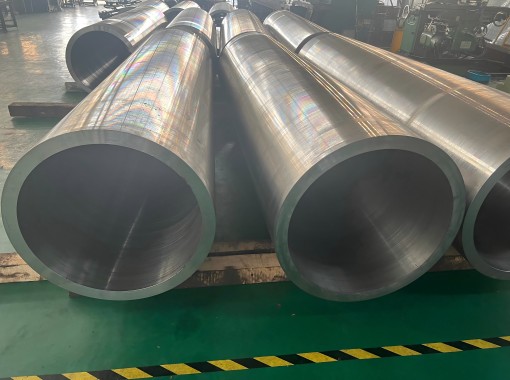

AISI 4140/42CrMo4 Ready to Honed Tube

AISI 4140/42CrMo4 Ready to Honed Tube

AISI 4140/42CrMo4 Ready to Honed Tube is a high-strength, low-alloy steel known for its excellent toughness, wear resistance, and fatigue strength. When manufactured into ready-to-honed tubes, it is widely used in hydraulic cylinders, piston rods, and other high-stress applications requiring precise internal dimensions and superior surface finish.

AISI 4140 / 42CrMo4 ready to honed tubes offer a high-performance solution for industries requiring precision, strength, and durability. Their superior mechanical properties and fine internal finish make them ideal for critical hydraulic and mechanical systems.

Advantages

1. High Strength: Excellent tensile and yield strength, suitable for heavy-duty applications.

2. Corrosion Resistance: The chromium content provides moderate corrosion resistance, making these tubes suitable for environments where oxidation and mild corrosion are concerns.

3. Seamless Construction: The seamless nature of the tube ensures uniformity and reliability in high-pressure applications.

4. Machinability: AISI 4140/42CrMo4 has good machinability in its annealed condition, allowing for easy fabrication into complex shapes.

5. Heat Treatability: AISI 4140/42CrMo4 ready to honed tube can be heat-treated to achieve desired mechanical properties, such as increased hardness or improved fatigue resistance.

6. Versatility: Suitable for a wide range of applications, including hydraulic cylinders, pneumatic cylinders, and precision engineering components.

Material Composition

| Element | AISI 4140 (ASTM) | 42CrMo4 (DIN/EN) |

|---|---|---|

| Carbon (C) | 0.38–0.43% | 0.38–0.45% |

| Chromium (Cr) | 0.80–1.10% | 0.90–1.20% |

| Molybdenum (Mo) | 0.15–0.25% | 0.15–0.30% |

| Manganese (Mn) | 0.75–1.00% | 0.60–0.90% |

| Silicon (Si) | 0.15–0.35% | 0.15–0.40% |

| Phosphorus (P) (max) | ≤0.035% | ≤0.025% |

| Sulfur (S) (max) | ≤0.040% | ≤0.035% |

| Iron (Fe) | Balance | Balance |

Mechanical Properties

| Property | Metric Units | Imperial Units |

|---|---|---|

| Tensile Strength | 850-1000 MPa | 123,000-145,000 psi |

| Yield Strength | 650-780 MPa | 94,000-113,000 psi |

| Elongation at Break | 12-18% | 12-18% |

Delivery Condition: SR,BK, BK+S, GBK, NBK

ID Size : 20mm – 1500mm

Length: max 16m

Type: Seamless, Hot Rolled, Cold Rolled, Cold Drawn

Straightness: ≤ 0.5/1000

Roughness: as request

Tolerance INT: as request

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or Plywood case

Delivery Conditions

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation.Appropriate further processing allows a certain degree of cold forming(e.g.bending,expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process.Subject to appropriate processing conditionsthe increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Contact Us

Interested in our products? Contact us for quotes, partnerships, or technical support!