Skived & Roller Burnished Tube

Main Products

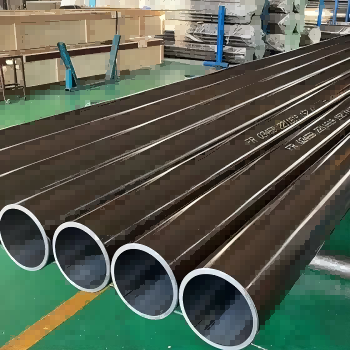

Skived & Roller Burnished Tube

Skived and Roller Burnished Tubes are precision-engineered tubes widely used in industries such as hydraulics, pneumatics, automotive, and aerospace. These tubes are known for their superior surface finish, dimensional accuracy, and durability. The manufacturing process involves two key steps:

1.Skiving:

Skiving is a machining process where the inner surface of the tube is cut to remove imperfections and create a smooth, uniform surface.

This step ensures the tube has a consistent inner diameter and prepares it for the next stage.

2.Roller Burnishing:

After skiving, the tube undergoes roller burnishing, where a hardened roller is pressed against the inner surface.

This process compresses the surface, improving its hardness, surface finish, and dimensional accuracy.

Roller burnishing also enhances the tube’s wear resistance and reduces friction, making it ideal for high-pressure applications.

Description of Skived & Roller Burnished Tube

Material: E355 ST52,STKM 13C, CK45,F1140, 4140,4130,4340, 42CrMo4,40CrMo,34CrMo4,35CrMo, SS304/316,Duplex 2205,etc.

Delivery Condition: SR,BK, BK+S, GBK, NBK

ID Size : 20mm – 1500mm

Length: max 16m

Type: Seamless, Hot Rolled, Cold Rolled, Cold Drawn

Straightness: ≤ 0.5/1000

Roughness: 0.1-0.4 u

Tolerance EXT: DIN2391, EN10305, GB/T 1619,GOST 8731,GOST 1050,GOST4543

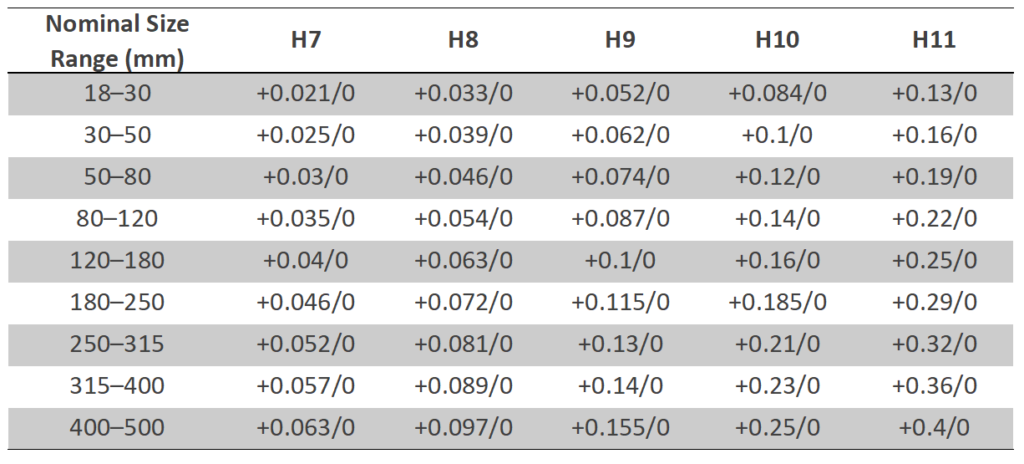

Tolerance INT: H7,H8,H9

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or Plywood case

ID Tolerance

Contact Us

Interested in our products? Contact us for quotes, partnerships, or technical support!