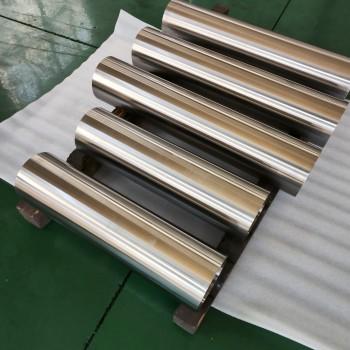

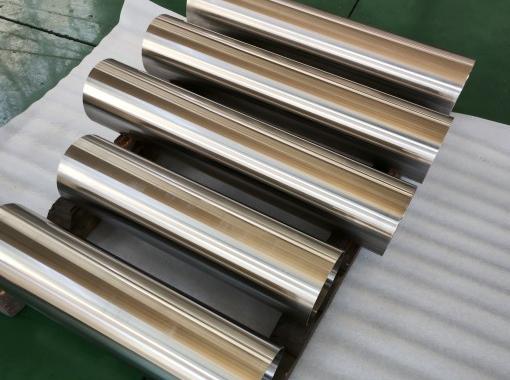

SS316 Polished Stainless Tube

SS316 Polished Stainless Tube

SS316 polished stainless steel tubes are high-quality, corrosion-resistant tubes made from Austenitic Stainless Steel 316, which contains molybdenum for enhanced resistance to corrosive environments. These tubes undergo a mechanical polishing process to achieve a smooth, reflective surface, improving aesthetics, hygiene, and corrosion resistance.

Advantages

1. Superior Corrosion Resistance: Molybdenum-enhanced (2-3%) for excellent resistance to chlorides, acids, and saltwater (ideal for marine, chemical, and coastal applications).Resists pitting, crevice corrosion, and stress corrosion cracking better than SS304.Suitable for harsh environments (e.g., offshore rigs, chemical plants, desalination).

2. Hygienic & Easy to Clean:Smooth polished surface of the SS316 polished stainless steel tube prevents bacterial adhesion.Non-porous & easy to sterilize – ideal for food processing, pharmaceuticals, and medical devices.

3. High Strength & Durability: Maintains structural integrity in high-pressure and extreme temperature conditions.Excellent weldability & formability (seamless and welded options available).Long service life with minimal maintenance.

4. Temperature Resistance: Performs well in both high and cryogenic temperatures (-200°C to 800°C).Used in heat exchangers, boilers, and refrigeration systems.

5. Low Maintenance & Cost-Effective: Does not require coatings or painting (saves long-term costs).Resistant to rust, staining, and degradation.

6. Versatility: Used across medical, food, marine, chemical, oil & gas, and semiconductor industries.

MATERIAL COMPOSITION:

Carbon (C): ≤0.08%

Manganese (Mn): ≤2%

Phosphorus (P): ≤ 0.0450%

Sulfur (S): ≤ 0.030%

Chromium (Cr): 16 – 18%

Nickel (Ni): 10 – 14%

Molybdenum(Mo): 2-3%

Iron (Fe): Balance

MECHANICAL Properties:

Tensile Strength: ~579 MPa

Yield Strength: ~290 MPa

Elongation: ~50%

Delivery Condition: SR,BK, BK+S, GBK, NBK

ID Size : 20mm – 1500mm

Length: max 16m

Type: Seamless, Hot Rolled, Cold Rolled, Cold Drawn

Service: Surface Polished,Chrome Plated,etc.

Straightness: ≤ 0.5/1000

Roughness: as request

Tolerance INT: H7,H8,H9,as request

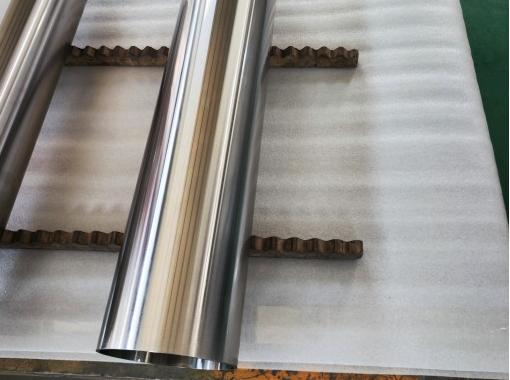

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or Plywood case

Delivery Conditions

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation.Appropriate further processing allows a certain degree of cold forming(e.g.bending,expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process.Subject to appropriate processing conditionsthe increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Contact Us

Interested in our products? Contact us for quotes, partnerships, or technical support!